Why Treat Condensate Drain Pans?

Drain pans can fill with slime, gunk, and disease-causing bacteria. This build-up comes from:

Condensation: Cooling equipment creates cold air by passing warm air over cooling coils. This causes condensate (water droplets) to form and flow off equipment coils — Think of a glass of ice cold ice tea on a hot summer day.

Drainage: Moisture from commercial cooling equipment is required to drain into a pan inside the unit to prevent condensate dripping out onto passerby and other objects. These pans are connected into drainage systems which is a potential cause for concern.

Bacteria: Slime is a by-product of bacteria which occurs naturally in water. Slime can build up and clog drain holes, causing the pan to overflow and potentially cause water damage. This also causes an ideal breeding ground for bacteria.

The Petri-dish Effect: Warm, standing water in pans work like Petri dishes, cultivating bacteria and potentially dangerous microorganisms. The equipment’s fan can then blow out the microbes into the facility degrading air quality and causing health risks.

Any property using air conditioning or refrigeration units need some sort of drain pan treatment.

Some Common Facilities Include:

- Apartment Buildings

- Commercial/Industrial Buildings

- Cruise Ships

- Hospitals

- Hotels and Motels

- Nursing Homes

- Office Buildings

- Schools and Universities

- Supermarkets

Any Properties using:

- Refrigerated Display Cases

- Ceiling Cooling Units

- Beverage & Grocery Reach-in Coolers

- Fan Coil Units

- Refrigerated Vending Machines

- Cool and Cold Storage Walk-Ins

- Roof-Top Units

How to install condensate drain treatments

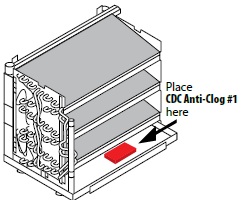

- Typically, treatments require that you place tablets or pan pads in the middle of the pan length. The product should begin working immediately after contact with water.

- Be careful that the treatment product is chosen with consideration of the drain size. You do not want a treatment to clog the drain hole and cause overflow. This is especially important for products that require you to remove an expended treatment dispenser.

- Each treatment should come with product specific instructions or be provided to you by the supplier.

For instructions on GWT CDC Anti-Clog #1 installation procedure, click this link.

Condensate Drain Pan Treatment Frequency:

- Treatment frequency depends on the size of the unit, operation frequency, and treatment type.

- We suggest continual treatment during months of operation for best results and to minimize risk of problems.

- GWT offers products for units between .5 ton and greater than 90 tons

Condensate Drain Pan Treatment Types:

There are many treatment options including chemical, dispensing, and registration differences:

Dispensing Methods:

Dissolvable Tablets/Blocks, Gels, Pads in a plastic dispensing mechanism, and Pads in a porous mesh

Chemical Property Considerations:

Percentage of biocide, pH neutralization, time-release

Registration:

Not all products have the same registrations and regulatory agencies may require a product that is NSF or EPA registered.

Warnings and Disclaimers: This web page is designed to provide information regarding the subject matter presented. It is produced with the understanding that neither GWT nor the contributors are rendering legal, medical, engineering or other professional services. Neither GWT nor the contributors shall be liable for damages, in any event, for incidental or consequential damages caused, or alleged to be caused, directly or indirectly, by the use of any information disclosed on this web page, including the use of any recommendations, methods, products, services, instructions or ideas.